Most read

MHP awarded with ULI prize

The Museum of Polish History in Warsaw, designed by the WXCA studio, was one of seven winners of the ULI Global Awards for Excellence 2024, awarded by the Urban Land Institute. Presented in the Arts and Culture category, the award is one of the highest international honours in the real estate and urban planning industry.

Eye to eye… with Paweł Sapek

This latest episode of 'Eye to Eye' is hot out of the podcast oven and ready to listen to! Eurobuild’s guest today is Paweł Sapek, the head of Prologis for Poland and the CEE region.

Chocolate museum set to open

The E.Wedel Chocolate Factory Museum is to open in Warsaw on September 4th, International Chocolate Day.

7R flexes its muscles at Kraków Airport

Polish warehouse developer 7R has completed the construction of 7R City Flex Kraków Airport I, close to Kraków-Balice airport.

House prices still rising

By the end of 2025, many residential projects launched in Warsaw in response to increased demand two years ago had been completed. This has contributed to a record high increase in the share of completed unsold units on offer to 19.6 pct, according to the latest data from CBRE and Tabelaofert.pl.

The night is worth billions

Why nighttime is no longer just a time for entertainment but is becoming part of urban, investment, and climate policy was discussed during the ULI Poland event "Places + Spaces: What Happens After Dark?", held at the Norblin Factory in Warsaw.

Prologis delivers fulfilment centre to Schaeffler

Prologis has delivered its new Eastern European Regional Distribution and Fulfilment Centre to automotive parts supplier Schaeffler, The centre in Ujazd, in the Opole region, comprises 62,500 sqm.

Wrocław becomes gateway to Europe

Wrocław is becoming a key logistics and technology hub in the CEE region, offering operational standards comparable to those in Germany or the Czech Republic while offering rental costs up to 40 pct lower, according to 'Wrocław, a City of Business Opportunities,' the latest report by Cushman & Wakefield.

PKO refinances ELI

Logistics platform European Logistics Investment secured EUR 136 mln in financing from PKO Bank Polski to refinance existing assets in the company's portfolio.

Boosteroid and DL Invest to build massive data centre

A joint venture between DL Invest Group and Boosteroid aims to develop one of the largest AI data centres in the region, with an initial IT capacity of 82 MW and scalability exceeding 1 GW.

Top stories

News

RSS Office & mixed-use development

Office & mixed-use development

Poland Enel Med stays on in Green2Day

The Enel-med medical centre in the Green2Day building in Wrocław has extended its lease and plans to transform the centre in response to the changing needs of patients.

Investment & finance

Investment & finance

Europe Urban Partners sells care homes

Urban Partners has announced the divestment of six modern care and nursing homes in Sweden on behalf of Nordic Strategies Fund III (NSF III). The portfolio has been acquired by Northern Horizon through its Aged Care Social Infrastructure Fund (ACSIF).

Warehouse & industrial

Warehouse & industrial

Poland Stable rents, reduced developer activity

We are entering 2026 with high levels of occupancy, limited new supply, and stable rents, according to the latest 'Warehouse and Industrial Market in Poland,' report by Savills.

Warehouse & industrial

Warehouse & industrial

Poland Two tenants stay on with P3

P3 Logistic Parks has announced two lease extensions at the P3 Poznań logistics park. The new agreements cover a total area of over 64,000 sqm in three buildings: DC1, DC3, and DC4.

Warehouse & industrial

Warehouse & industrial

Poland Bremer builds for AJS Parts

Bremer will build a modern warehouse for automotive parts distributor AJS Parts. The 30,000 sqm BTS centre is to be built in Jawczyce, Ożarów Mazowiecki.

Retail & leisure

Retail & leisure

Poland Big Ostroda becomes bigger

Acteeum is to expand the Big Ostróda retail park by a further 4,000 sqm gla and the addition of a Popeyes restaurant. The new restaurant building is scheduled to open in September, with the new retail space to open in Q1 2027.

Office & mixed-use development

Office & mixed-use development

Poland Dom Development stays on in Metropolitan

Residential developer Dom Development has extended its lease in the Metropolitan building on Plac Piłsudskiego in Warsaw and taken on additional space. The company’s lease will now comprise 4,000 sqm of office space.

Warehouse & industrial

Warehouse & industrial

Poland Panattoni to build for Nagel

Panattoni is to build a BTS project for food-distribution company Nagel-Group BTS project in Poznań in Panattoni Park Poznań East III. A total of 46,000 sqm of modern warehouse and office space will be developed, with the development set to become Nagel-Group’s key centre in Poland.

Investment & finance

Investment & finance

Hungary Park Center portfolio disposal completed

Revetas Capital,, has announced the finalisation of the sale of the Park Center Hungary portfolio to Gránit Asset Management acting on behalf of Magyar Posta Takarék Real Estate Investment Fund.

Warehouse & industrial

Warehouse & industrial

Poland Sportano increases lease size with Panattoni and Accolade

Panattoni and Accolade have signed a new agreement with Sportano, one of the fastest growing Polish e-commerce platforms in the sports segment. The agreement covers the extension of the tenant's existing lease and an expansion by an additional 14,846 sqm, giving a total of 27,300 sqm at Panattoni Park Zielona Góra II. As a result, the park is now fully commercialised.

Investment & finance

Investment & finance

Czech Republic Fidurock buys two Prague townhouses

The real estate investment group Fidurock has purchased two historic apartment buildings at Sokolská 35 and Sokolská 37 in the immediate vicinity of Wenceslas Square.

Retail & leisure

Retail & leisure

Poland Pasaż Dominikański to open soon

Pasaż Dominikański in Tarnobrzeg has been granted an occupancy permit and is scheduled to open in mid-March.

Retail & leisure

Retail & leisure

Poland Lee Cooper expands in Designer Outlet Gdańsk

The Lee Cooper store at Designer Outlet Gdańsk has expanded from 180 sqm to over 250 sqm. Lee Cooper has been in the centre since 2008.

Retail & leisure

Retail & leisure

Poland Worldbox enters Focus Mall

The Modivo Group is strengthening its presence in Focus Mall Zielona Góra with the opening of a new worldbox store in the shopping centre. Additionally, the CCC store in the centre has also increased in size.

Magazine

Edition 2 (305) February 2026

One year to the next

Welcome to the first issue of Eurobuild CEE of 2026! It comes to you following another highly enjoyable Eurobuild Awards Gala, which set the seal on the successes of the previous y ...

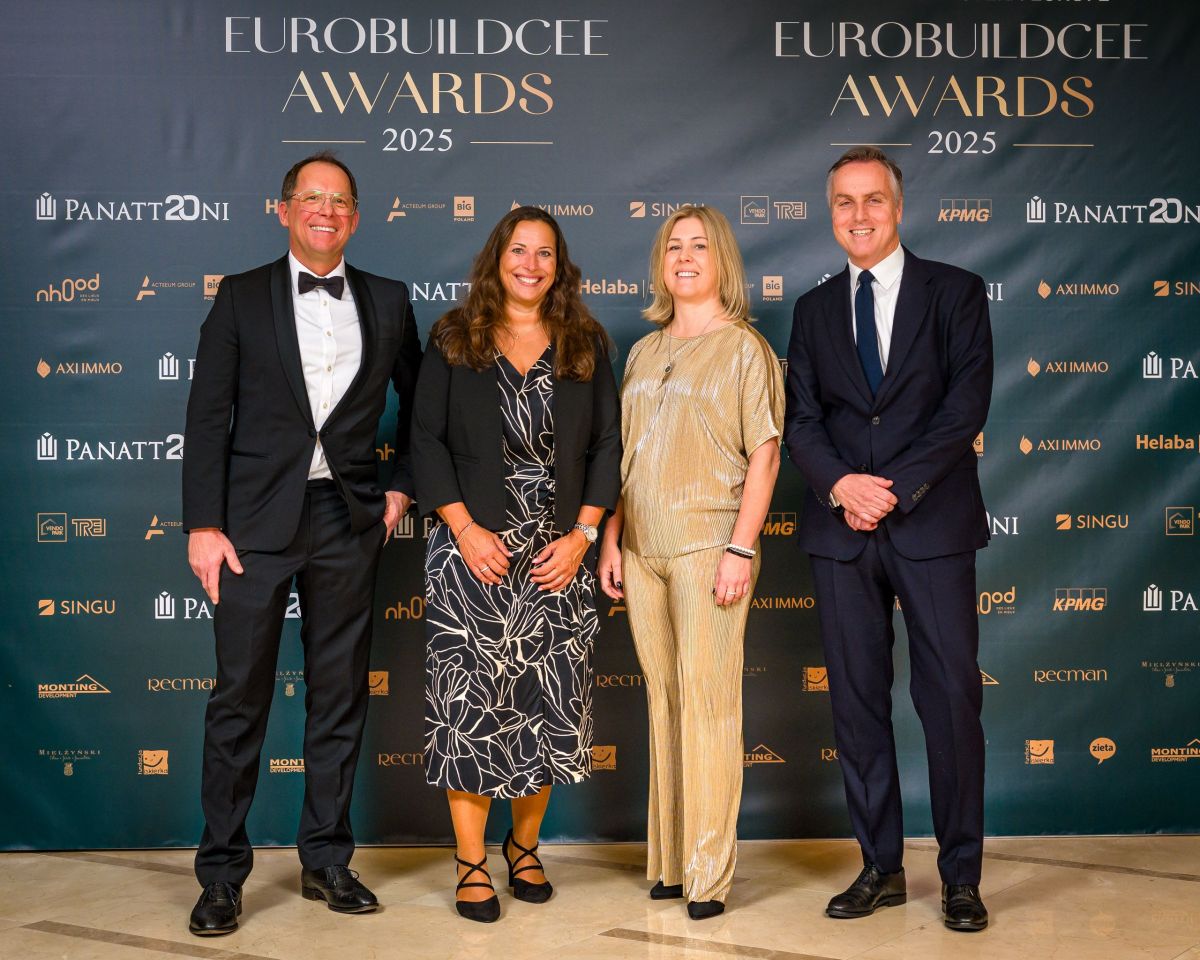

Eurobuild AwardsFifteen years of fame

The 15th Eurobuild Awards Gala brought 2025 to a positive close for the real estate market. All the major players in the industry were assembled once again in the biggest ballroom ...

Eurobuild AwardsIn the words of the winners...

The winners of the Eurobuild Awards 2025 give us their reactions on receiving these honours.

Eurobuild AwardsThe confidence to show the way forward

No one who has been acquainted with the Polish residential market over the last 30 years could deny that the latest recipient of the Lifetime Achievement Award fully deserves this ...

Small talkNot just opening doors

Maciej Grabowski, the CEO and founder of Blue Bolt, tells us how his company's building access platform is what property managers need - not just for opening doors, but for intergr ...

Small talkFocusing our energy

Power purchase agreements (PPAs) may just be the solution for energy cost optimisation and hitting decarbonisation targets in times of economic and geo-political uncertainty, accor ...

Podcasts

More podcasts arrow_forward headset

headsetThe power of community

headset

headsetA breath of fresh air from France, or comments from Cannes part 3

headset

headsetA breath of fresh air from France, or comments from Cannes part 2

headset

headsetPoland versus the West

headset

headsetWhat's on the horizon in Munich? Part II

headset

headsetWhat's on the horizon in Munich?

headset

headsetDamian Grzywacz and Bartosz Szumski on the development of The Form building

headset

headsetJarosław Szanajca and Marcin Rams on the Kraków housing market

headset

headsetMateusz Polkowski on the market transformation since Poland's EU accession

headset

headsetSebastian Sołtys on the development plans of LPP Logistics

Eurobuild TV

More videos arrow_forward play_circle_outline

play_circle_outlineEurobuild's special Christmas event 2022

play_circle_outline

play_circle_outlineThe 2022 Eurobuild Awards Gala

play_circle_outline

play_circle_outlineThe Christmas chain gang

play_circle_outline

play_circle_outlineThe Eurobuild Awards Gala 2020

play_circle_outline

play_circle_outlineApril 2, World Autism Awareness Day

play_circle_outline

play_circle_outlineTax revolution for real estate

play_circle_outline

play_circle_outlineLight it up Blue

play_circle_outline

play_circle_outlineThe 10th Eurobuild Awards Gala

play_circle_outline

play_circle_outlineRobert Dobrzycki's Outstanding Contribution to the Real Estate Market

play_circle_outline

play_circle_outlineThe many advantages of forward funding

Panelists

Categories

Architecture and urban planning

Dance centre opens in Warsaw

The Dance and Performing Arts Pavilion has opened in Warsaw's Powiśle district.

Public consultations held for Park Wilanów

Need for clarity introducing reforms

Construction

Dekpol debuts in Romania with 20,000 sqm logistics park

Dekpol Budownictwo is eentering Romania. In December 2025, the company signed an agreement with a developer to carry out design work for the first sta ...

Construction industry waiting to boom

Warsaw returns another building to its prime

Coronavirus

Vaccination centre provided by Globalworth

The Globalworth Foundation has provided the authorities in Bucharest with office space for a Covid vaccination centre.

Employers in no rush to return to workplaces

Catella sees hope and chances for real estate after Covid-19

Corporate social responsibility

Not only for horses

Panattoni BTS and Commercecon together support the establishment of the second Centaurus Foundation centre in Poland to help horses and other animals.

Panattoni sticks to the fairway

Colliers ends operations in Russia, Belarus

E-commerce

This is the end

Shopee is ending its operations in Poland. The Asian e-commerce platform, which debuted in Poland in 2021, intends to focus on operations in other reg ...

Wildberries now growing in Ukraine

Wildberries growing in April

ESG

Retro Office now accessible

The Retro Office House office building in Wrocław, owned by Globalworth, has received a Building Without Barriers certificate from the Integracja Foun ...

Platinum for Premium Point and Plaza

PPA for Signum Work Station

Eurobuild Awards

All the winners of the EurobuildCEE Awards 2025!!

The 15th EurobuildCEE Awards Gala is now behind us and all the winners can be revealed! Special congratulations go to Kazimierz Kirejczyk, who was pre ...

The winners of the Eurobuild Awards 2024!

Call for nominations and jury members!

Eurobuild FM

The power of community

We spoke with Zdena Noack, managing director of Zeitraum Student Housing, during the opening of Zeitraum Racławicka in Kraków.

A breath of fresh air from France, or comments from Cannes part 3

A breath of fresh air from France, or comments from Cannes part 2

EurobuildCEE

The latest issue of Eurobuild has hit the shelves!

The latest issue of Eurobuild CEE magazine is now out, in print, web and flipbook versions! And it contains the usual mix of hot news, analysis, trend ...

The December issue of Eurobuild hits the shelves!

The latest issue of Eurobuild hits the shelves!

Events

The night is worth billions

Why nighttime is no longer just a time for entertainment but is becoming part of urban, investment, and climate policy was discussed during the ULI Po ...

Register now for bieg na szczyt

MIPIM finalists announced

Exclusive

Our plans are ambitious

Recently, Martin Ohly was appointed to the newly created position of head of Germany at 7R, so what better opportunity could there be to find out abou ...

Our plans are ambitious

From Tallinn to Dubrovnik

Eye to eye

Eye to eye… with Władysław Grochowski

After a long break, we invite you to hot episode of the "Eye to eye" podcast! Today we talk with Władysław Grochowski, the head and founder of Arche.

Eye to eye… with Paweł Sapek

Eye to eye with… Daniel Bienias

For Ukraine

Nansen Refugee Award goes to Poland!

The UN Nansen Refugee Award award will go to Poland for the first time. According to the office of the UNHCR High Commissioner this year's regional wi ...

Build Europe supports refugees and appeals to European Commission

Former Russian building to house Ukrainian refugees

Green projects

EIB grants CTP solar-powered €200m loan

Czech developer CTP has been granted a EUR 200 mln loan from the European Investment Bank for the roll-out of its large-scale solar panel installation ...

Cromwell granted €66m green loan for Janki

Pad Res to build 2 PV farms in Pomerania

Hotels

Lithuanians construct hotel in Gdańsk

Construction work on a hotel has been launched in the Wrzeszcz district of Gdańsk. Lithuanian 1 Asset Management is the investor and the developer is ...

ibis Styles open in Tbilisi

Mercure opens in Bucharest

Human resources

Change at the top for ULI Europe

The Urban Land Institute (ULI) has appointed Simon Durkin as Chief Executive Officer Europe, ULI, succeeding Lisette van Doorn, commencing early March ...

ULI announces new chairs

Panattoni bets big on data centres

Infrastructure

Intercor to build Piaski-Dorohucza

Intercor has obtained a permit for a road project for the Piaski-Dorohucza section of the S12 expressway. The design-build contract, worth PLN 357 mln ...

Połaniec 2 substation under construction

Budimex builds more roads

Interior design

New food hall in Poznań

The Wiedeńska Town House in the centre of Poznań, which dates back to the early 20th century, has been renovated and converted into a food hall with i ...

New look for Eurocentrum lobby

New look for Otis offices

Investment & finance

Urban Partners sells care homes

Urban Partners has announced the divestment of six modern care and nursing homes in Sweden on behalf of Nordic Strategies Fund III (NSF III). The por ...

Park Center portfolio disposal completed

Fidurock buys two Prague townhouses

Land acquisitions

Panattoni enlarges its Swedish portfolio

Panattoni has acquired two properties near Gothenburg, Sweden. The brownfield sites will be replaced by a modern 43,000 sqm facility.

CTP purchases land in Kragujevac

CTP secures major brownfield site

Material partner

Brownfield rather than greenfield – a model for sustainable development at City Point Targówek

Contemporary cities are grappling with the challenge of fostering dynamic growth while alleviating environmental pressures. Traditional infrastructure ...

Nordbygg 2024: Many innovations and strong interest

Excellent Fern at Off Piotrkowska

Office & mixed-use development

Enel Med stays on in Green2Day

The Enel-med medical centre in the Green2Day building in Wrocław has extended its lease and plans to transform the centre in response to the changing ...

Dom Development stays on in Metropolitan

Il Tramonto 2.0 opens in West Gate

Property and Facility Management

Balmain takes on Adventum

The Balmain Group has taken over the management of a portfolio of four warehouses owned by Adventum International. The properties, totalling around 18 ...

Savills to manage for Yareal

Studio B under new management

Public buildings

Oleśnica railway station restored

The reconstruction of the historic Oleśnica railway station, dating back to 1868, is nearing completion. A dedicated passenger area has been created, ...

Warsaw Uni building underway

MHP awarded with ULI prize

Residential

Antczak given the go-ahead for Twarda 7

A modern residential and commercial building will be built at ul. Twarda 7 in Warsaw. The Antczak Group has been granted a building permit for the pro ...

IMV to manage Słowackiego

Strabag to build for Alesonor

Retail & leisure

Big Ostroda becomes bigger

Acteeum is to expand the Big Ostróda retail park by a further 4,000 sqm gla and the addition of a Popeyes restaurant. The new restaurant building is s ...

Pasaż Dominikański to open soon

Lee Cooper expands in Designer Outlet Gdańsk

Technology

Rentujemy to revolutionise the market

Polish technology company Rentujemy, which is involved in short-term rental management, is launching a co-hosting service. With this solution, the com ...

Velis has a new name

Symbiotic fit for HB Reavis and HqO

Warehouse & industrial

Stable rents, reduced developer activity

We are entering 2026 with high levels of occupancy, limited new supply, and stable rents, according to the latest 'Warehouse and Industrial Market in ...

Strong warehouse sector whilst capital cautious and offices yet to rebound

Strong warehouse sector whilst capital cautious and offices yet to rebound

Newmark Polska

Poland’s commercial real estate market enters 2026 in good health and with solid growth potential. Warehouses remain one of the strongest sectors in Europe, while constrained ...

The end of greenwashing as flex grows in strength

The end of greenwashing as flex grows in strength

Walter Herz

The office sector is entering a period of deeper qualitative and financial scrutiny. Decisions regarding new projects, refurbishments, or leasing are now supported by more thorough ...

The quiet revolution in Małopolska

The quiet revolution in Małopolska

Axi Immo

Developers across the region are increasingly favouring heat pumps and photovoltaic systems over traditional gas boilers in warehouse construction. This shift marks a growing commi ...